Milk Factory

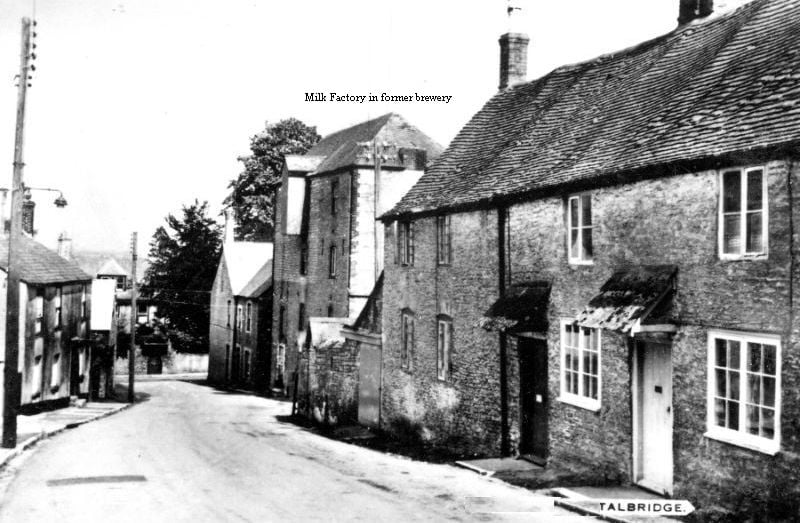

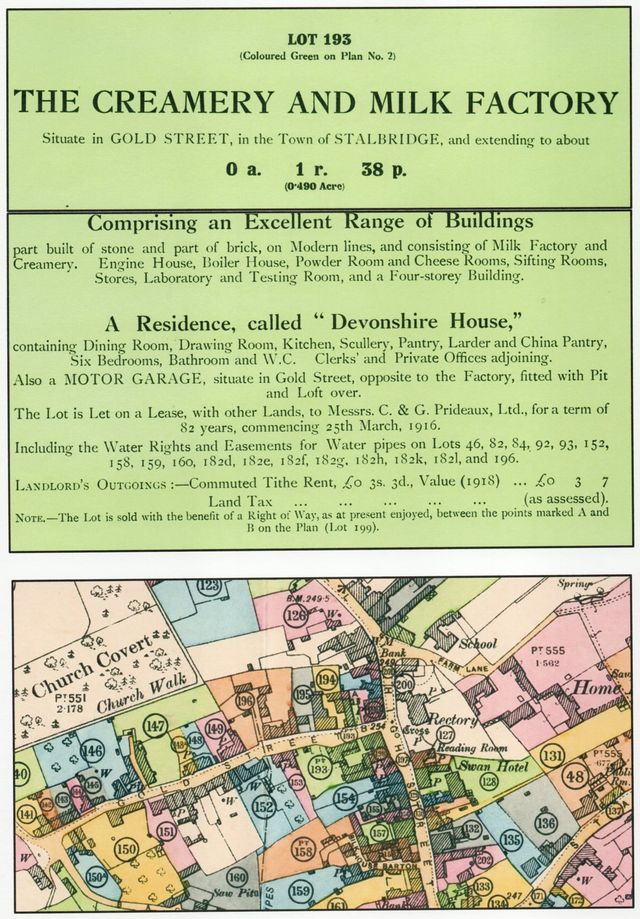

Listed as Lot 197 in the Stalbridge Estate sale catalogue is the C and G Prideaux milk factory, located in a former brewery building at the lower end of Gold Street. The milk factory was the largest local employer, with milk delivered to the factory in churns by pony and trap and later by lorry. Milk was transported by railway to a distribution depot at Poole and also turned into powder flakes on the premises.

The Prideaux family originally came from Cornwall. Charles branch of the family settled in the Barnstable area of Devon. William Prideaux was a railway porter, and later a signalman and his wife a Nurse. They lived in a railway carriage with their seven children, of whom Charles was the second. Charles left school at the age of twelve. His first job was as a messenger boy at Barnstable station telegraph office, where he learnt to operate the telegraph and also took on the duties of ticket clerk. He wore a bowler hat and stood on a box behind the ticket window to appear to be taller and older. His pay was 10 shillings a week. Charles saw the opportunity to earn some extra money by making ginger beer and selling it in the waiting room for a small profit. He also began to broaden his education by reading.

By the time he was eighteen Charles had moved to Semley Station where he was working as the Goods Clerk, with a salary of £100.00 per year. During his time at Semley, Charles began visiting local farms to buy eggs, when he probably met his future wife Veronica, a farmer’s daughter from East Knoyle. They married in 1876. Charles managed to accumulate enough capital to start his own business by buying “the gate at Semley fete and pony races, a popular event attracting as many as 3000 entrants, on two consecutive years. The two “gates” earned him a profit of £70.00d. He invested some of this money by purchasing a pony and cart, enabling him to widen his catchment area and to buy butter and rabbits in addition to eggs. In 1878 he and Veronica moved to a cottage on the Motcombe Estate and later that year he gave up his job on the railway and started out on his own.

The next venture was buying poultry, game and pigs. Bacon, sausages, cheese and milk were produced and a small creamery built at Motcombe, with his brother George put in charge at the age of 23. The brothers then started the transportation of milk by rail and grew the business by developing other sites along the mainline railway to London. The former Whites brewery, in Gold Street, Stalbridge, was leased from the Stalbridge Estate, opening as a creamery and milk factory, in 1892. After his marriage George moved to Devonshire House, and took over the management of the creamery in Gold Street. Working alongside his elder brother they developed the business to become one of the largest concerns of its kind in the South West of England. Charles’ most important achievement was the production of edible casein from separated milk. Casein is the principal protein contained in cow’s milk. This product was branded as ‘casumen’ and in 1900 the two brothers formed the Prideaux Pure Casein and Milk Food Company Ltd. In 1902, the steam-heated cylinders, used for making the casumen, were utilised to produce dry milk powder.

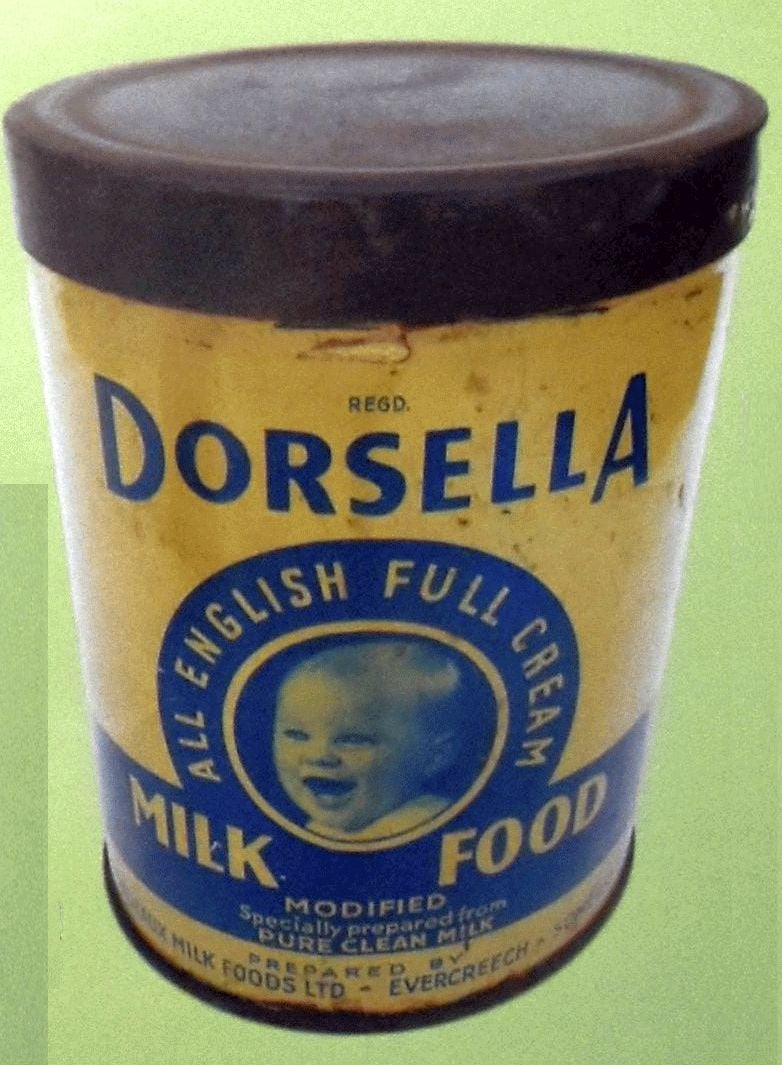

During World War 1 a full cream milk powder, called Dorsella, was produced. Fresh milk was emptied into a holding tank rom 17 gallon churns, pasteurized and the cooled. Central rollers which were steam heated, rotated, and the milk dripped through perforations and then picked up by the rollers. These evaporated the water content in the milk and left a residue of milk powder which dropped into a collecting tray located underneath the roller, scooped out by hand before passing through a wire mesh screen to finely sift the powder.

On the 1st August 1914, with a total of eight creameries, located at Motcombe, Stalbridge, Shillingstone, Evercreech, Mere and Castle Cary, C and G Prideaux Ltd became incorporated. The provision, bacon and poultry business traded separately as Charles Prideaux.

At the Stalbridge estate auction sale George Prideaux purchased the freehold of the Gold Street premises, including Devonshire House, which provided office accommodation for the administrative staff, employed by the milk factory. A single storey building, with a loft, directly opposite the factory provided a garage and workshop for the repair and maintenance of vehicles.

World War 1 had resulted in many changes, including an increase in government contracts for the supply of dried milk for military hospitals. Women replaced men in the workforce as they were called up for military service. Shortly after his 80th birthday, in 1933, Charles gave an interview to a national newspaper, revealing that the milk business was handling 10,000 gallons of milk a day. The total turnover during the war years had amounted to £1million pounds a year, with a workforce of 200 and the transport costs, for the operation of 40 lorries, £30,000.00d a year. The company had its own printing works in Gillingham, where all of the packaging was produced.

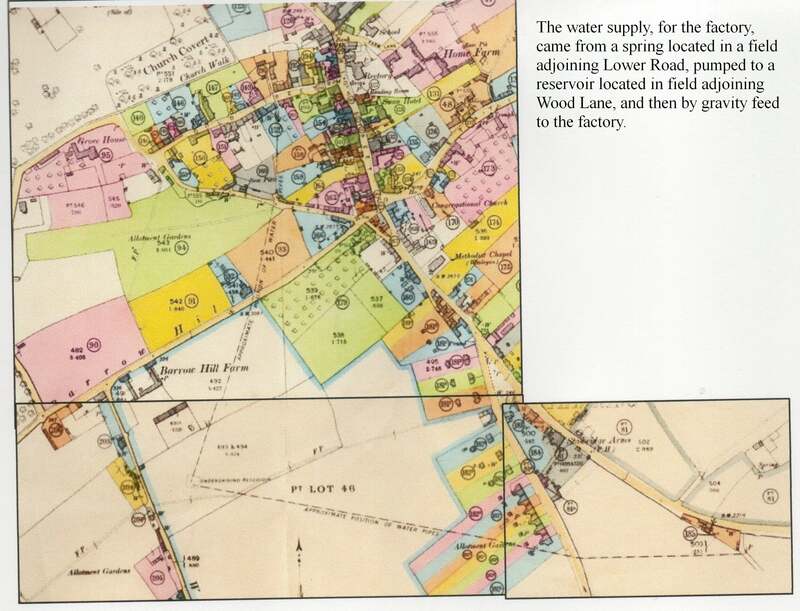

The water supply for the factory came from a spring located in a field adjoining Lower Road, pumped to a reservoir located in field adjoining Wood Lane, and then by gravity feed to the factory.

C and G Prideaux had several other milk depots in the Blackmore Vale and a factory at Motcombe producing bacon and other meat products

Charles died in 1940 at the age of 87. In 1945 the Cow and Gate Group acquired a controlling interest. The Prideaux Pure Casein and Milk Food Company Ltd was renamed Prideaux Milk Foods Ltd. George died at the age of 84 and was replaced by his son Lionel, who had joined the business in 1915. Lionel’s son joined the firm in 1955 and was appointed manager of the Motcombe factory. Cow and Gate acquired full control of the Prideaux companies in 1959, when the Stalbridge milk factory closed. The former brewery building was demolished and the buildings at the rear, initially used as a distribution depot for Robertson's jam and in the mid- 1960s converted to a garage for the servicing, and repair, of motor vehicles. These buildings have now been demolished making way for a residential development. The Prideaux family name ceased to exist in 1967 when the business was sold to Case and sons Ltd.

The Prideaux family originally came from Cornwall. Charles branch of the family settled in the Barnstable area of Devon. William Prideaux was a railway porter, and later a signalman and his wife a Nurse. They lived in a railway carriage with their seven children, of whom Charles was the second. Charles left school at the age of twelve. His first job was as a messenger boy at Barnstable station telegraph office, where he learnt to operate the telegraph and also took on the duties of ticket clerk. He wore a bowler hat and stood on a box behind the ticket window to appear to be taller and older. His pay was 10 shillings a week. Charles saw the opportunity to earn some extra money by making ginger beer and selling it in the waiting room for a small profit. He also began to broaden his education by reading.

By the time he was eighteen Charles had moved to Semley Station where he was working as the Goods Clerk, with a salary of £100.00 per year. During his time at Semley, Charles began visiting local farms to buy eggs, when he probably met his future wife Veronica, a farmer’s daughter from East Knoyle. They married in 1876. Charles managed to accumulate enough capital to start his own business by buying “the gate at Semley fete and pony races, a popular event attracting as many as 3000 entrants, on two consecutive years. The two “gates” earned him a profit of £70.00d. He invested some of this money by purchasing a pony and cart, enabling him to widen his catchment area and to buy butter and rabbits in addition to eggs. In 1878 he and Veronica moved to a cottage on the Motcombe Estate and later that year he gave up his job on the railway and started out on his own.

The next venture was buying poultry, game and pigs. Bacon, sausages, cheese and milk were produced and a small creamery built at Motcombe, with his brother George put in charge at the age of 23. The brothers then started the transportation of milk by rail and grew the business by developing other sites along the mainline railway to London. The former Whites brewery, in Gold Street, Stalbridge, was leased from the Stalbridge Estate, opening as a creamery and milk factory, in 1892. After his marriage George moved to Devonshire House, and took over the management of the creamery in Gold Street. Working alongside his elder brother they developed the business to become one of the largest concerns of its kind in the South West of England. Charles’ most important achievement was the production of edible casein from separated milk. Casein is the principal protein contained in cow’s milk. This product was branded as ‘casumen’ and in 1900 the two brothers formed the Prideaux Pure Casein and Milk Food Company Ltd. In 1902, the steam-heated cylinders, used for making the casumen, were utilised to produce dry milk powder.

During World War 1 a full cream milk powder, called Dorsella, was produced. Fresh milk was emptied into a holding tank rom 17 gallon churns, pasteurized and the cooled. Central rollers which were steam heated, rotated, and the milk dripped through perforations and then picked up by the rollers. These evaporated the water content in the milk and left a residue of milk powder which dropped into a collecting tray located underneath the roller, scooped out by hand before passing through a wire mesh screen to finely sift the powder.

On the 1st August 1914, with a total of eight creameries, located at Motcombe, Stalbridge, Shillingstone, Evercreech, Mere and Castle Cary, C and G Prideaux Ltd became incorporated. The provision, bacon and poultry business traded separately as Charles Prideaux.

At the Stalbridge estate auction sale George Prideaux purchased the freehold of the Gold Street premises, including Devonshire House, which provided office accommodation for the administrative staff, employed by the milk factory. A single storey building, with a loft, directly opposite the factory provided a garage and workshop for the repair and maintenance of vehicles.

World War 1 had resulted in many changes, including an increase in government contracts for the supply of dried milk for military hospitals. Women replaced men in the workforce as they were called up for military service. Shortly after his 80th birthday, in 1933, Charles gave an interview to a national newspaper, revealing that the milk business was handling 10,000 gallons of milk a day. The total turnover during the war years had amounted to £1million pounds a year, with a workforce of 200 and the transport costs, for the operation of 40 lorries, £30,000.00d a year. The company had its own printing works in Gillingham, where all of the packaging was produced.

The water supply for the factory came from a spring located in a field adjoining Lower Road, pumped to a reservoir located in field adjoining Wood Lane, and then by gravity feed to the factory.

C and G Prideaux had several other milk depots in the Blackmore Vale and a factory at Motcombe producing bacon and other meat products

Charles died in 1940 at the age of 87. In 1945 the Cow and Gate Group acquired a controlling interest. The Prideaux Pure Casein and Milk Food Company Ltd was renamed Prideaux Milk Foods Ltd. George died at the age of 84 and was replaced by his son Lionel, who had joined the business in 1915. Lionel’s son joined the firm in 1955 and was appointed manager of the Motcombe factory. Cow and Gate acquired full control of the Prideaux companies in 1959, when the Stalbridge milk factory closed. The former brewery building was demolished and the buildings at the rear, initially used as a distribution depot for Robertson's jam and in the mid- 1960s converted to a garage for the servicing, and repair, of motor vehicles. These buildings have now been demolished making way for a residential development. The Prideaux family name ceased to exist in 1967 when the business was sold to Case and sons Ltd.

Dave Harris

Yet another interesting read and thanks for the tremendous effort needed to assemble the information. I lived in Devonshire House roughly from 1954 until after the factory closed. My father, along with Sid Scott and Tommy Breaden, were lorry drivers. To this day I recall the reg BFX 30 of the first lorry I remember my father driving (1950's). At that time, lorries were stored overnight in the premises on the opposite side of Gold Street. Until prompted, I can’t recall many of the other workers, but Jim Turner worked tipping the milk and sterilising the (by then ten gallon) churns, and Jasper Turvey was an engineer. Frank Harris (my great uncle) worked in the daily operations office, and Elsie Harris (my great aunt) was secretary to Mr Prideaux. The main office fronted onto the High Street, fitted out just as you’d see it in old films of the period (large oak desks, telephone on a tall filing cabinet etc). The office also had a strong room.

The factory area had a lower yard and top yard. Off the lower yard (in the building that fronted to Gold Street), the milk was in stirred the large tubs to make curds and whey. Across the yard were the machine(s) with a heated roller to make the dried milk. Excess flakes collected at the edges and were often a gift.

Cheese could be taken to the cold store near Motcombe / Evercreech (?? which), and anyone who’s been in such a place will recall the sight and smell (and probably a small test sample) of slowly maturing cheeses. The excess milk was taken usually to Kings Stag and then to the creameries at Oakdale where it was tipped, bottled and then distributed in the afternoon. Gold top, TT and silver top in pints, halves and thirds (for schools).

After the Stalbridge factory closed, milk collection was still required so the lorries remained operational until 1963-4 (when I assume bulk collection began?). At that date, the Stalbridge drivers were made redundant.

After a period Dave Mullet took over the factory premises, first establishing his haulage business and later, Stalbridge Motors. The staple haulage loads were the jams and “Chunky” marmalade Philip mentions, but soaps and shampoos (Wright’s) were also included along with crisps and other snacks. Distribution was mainly to Devon and Cornwall.

The image below shows a milk collection lorry in winter 1963 at Thornhill. Oakdale heading. Driver Frank Harris, middle Jim Turner and right Sid Scott.

Yet another interesting read and thanks for the tremendous effort needed to assemble the information. I lived in Devonshire House roughly from 1954 until after the factory closed. My father, along with Sid Scott and Tommy Breaden, were lorry drivers. To this day I recall the reg BFX 30 of the first lorry I remember my father driving (1950's). At that time, lorries were stored overnight in the premises on the opposite side of Gold Street. Until prompted, I can’t recall many of the other workers, but Jim Turner worked tipping the milk and sterilising the (by then ten gallon) churns, and Jasper Turvey was an engineer. Frank Harris (my great uncle) worked in the daily operations office, and Elsie Harris (my great aunt) was secretary to Mr Prideaux. The main office fronted onto the High Street, fitted out just as you’d see it in old films of the period (large oak desks, telephone on a tall filing cabinet etc). The office also had a strong room.

The factory area had a lower yard and top yard. Off the lower yard (in the building that fronted to Gold Street), the milk was in stirred the large tubs to make curds and whey. Across the yard were the machine(s) with a heated roller to make the dried milk. Excess flakes collected at the edges and were often a gift.

Cheese could be taken to the cold store near Motcombe / Evercreech (?? which), and anyone who’s been in such a place will recall the sight and smell (and probably a small test sample) of slowly maturing cheeses. The excess milk was taken usually to Kings Stag and then to the creameries at Oakdale where it was tipped, bottled and then distributed in the afternoon. Gold top, TT and silver top in pints, halves and thirds (for schools).

After the Stalbridge factory closed, milk collection was still required so the lorries remained operational until 1963-4 (when I assume bulk collection began?). At that date, the Stalbridge drivers were made redundant.

After a period Dave Mullet took over the factory premises, first establishing his haulage business and later, Stalbridge Motors. The staple haulage loads were the jams and “Chunky” marmalade Philip mentions, but soaps and shampoos (Wright’s) were also included along with crisps and other snacks. Distribution was mainly to Devon and Cornwall.

The image below shows a milk collection lorry in winter 1963 at Thornhill. Oakdale heading. Driver Frank Harris, middle Jim Turner and right Sid Scott.

Dave Harris

Thanks to Chris Hughes for reminding me of the attached image which (with earlier help from Dick Curtis) allows me to add a few more names of employees at the Milk Factory.

Those shown are:

Back: Bob Senior, Bert West(?), Jim Turner

Front: George Hatcher, Jimmy Fudge, Jasper Turvey, Fred Aish.

There is an earlier photograph of factory workers, but I'll leave that for someone who can also identify the individuals.

Thanks to Chris Hughes for reminding me of the attached image which (with earlier help from Dick Curtis) allows me to add a few more names of employees at the Milk Factory.

Those shown are:

Back: Bob Senior, Bert West(?), Jim Turner

Front: George Hatcher, Jimmy Fudge, Jasper Turvey, Fred Aish.

There is an earlier photograph of factory workers, but I'll leave that for someone who can also identify the individuals.